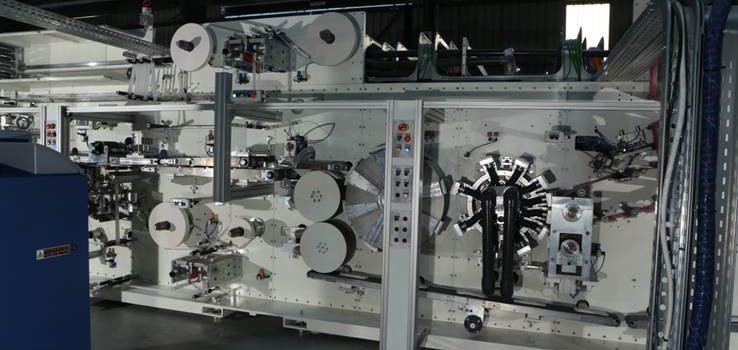

Retrofit Units for Diaper Machines

Phoenix Machinery Hygiene Converting Division manufactures and retrofits

Diaper Machines with the following equipments:

Low Waste Back Ears Unit (BEU)

Diaper Low Waste Back Ears (BEU) is a unit for forming, cutting and

placing shaped back ears. BEU is a servo driven low waste system

developed to guarantee high-speed performance up to 600 cuts/min.

The new generation of SIEMENS drives has been introduced to

guarantee high flexibility and easy job change between different sizes

through the operator panel and minor mechanical adjustments.

Up to 600 cuts/min

Stretch raw material width from 140 to 180 mm

Cutting length from 75 to 90 mm

Diaper chassis width from 240 to 260 mm

Frontal Tape Cut & Place (FTCP)

Frontal Tape Cut and Place (FTCP) is a unit for pulling, gluing, cutting

and placing the frontal tape.

Up to 600 cuts/min

Frontal tape width up to 240 mm

Diaper chassis width up to 380 mm

Independent servo driven system

Raw material unwinding with automatic splicing system

Safe feeding system

Torque limiting device with phase shifting unit (optional)

Hot melt system (optional)

Refastenable Tape Cut & Place (RTCP)

Refastenable Tape Cut and Place (RTCP) is a unit for pulling, cutting

and placing the pre-glued tab tape. The cutting device is followed by a

tape folding and pressing system.

Up to 600 cuts/min

Tape width up to 65 mm

Independent servo driven system

Diaper chassis width up to 380 mm

Torque limiting device with phase shifting unit (optional)

Sublayer Cut & Place (SLCP)

SLCP is a unit for pulling, cutting and placing the sublayer (ADL).

Up to 600 cuts/min

ADL width up to 100 mm

Cutting length up to 270 mm

Diaper chassis width up to 380 mm

Independent servo driven system

Raw material unwinding with automatic splicing system

Safe feeding system

Hot melt system (optional)

Torque limiting device with phase shifting unit (optional)

Horizontal Stacking & Counting System (HSC)

Phoenix HSC is a unit that receives bi-fold or tri-fold products from the

parent machine. The products are grouped into a stack and delivered

to a manual or auto packing machine.

Up to 50 cycles/min

Stack count from 8 to 36 diapers

Single or dual pushing systems

All functions are servo driven

Automatic job change from Human Machine Interface (HMI)

Backsheet Lamination Unit (BLU)

The backsheet lamination unit consists of:

Two unwinders with splice & buffer for polyethylene & non-woven material

Hot melt glue system for lamination

Automatic edge guiding systems for PE & N/W before the mating point

Pulling and lamination unit

Control panel with Human Machine Interface (HMI)

Production speed up to 300m/min

Material width up to 380 mm

2 Comments

Hassan Halawi

13/05/2020 at 6:15 am

Please we need the final price

Oualid

22/06/2020 at 4:42 pm

Hi, can you give me a quote for the machine, and what is the date of manufacture.

Best regards,