Phoenix Machining Services

Phoenix CNC center is a professional manufacturer of precision machined

products designed to meet customer specifications. The center is made up of

a versatile manufacturing environment of over 20 CNC machine tools capable

of answering the stringent demands of various industries.

Machining Capabilities

Full multi-axis turning capabilities

Full multi-axis high speed milling capabilities

CNC wire cut

CNC plasma cutting

Grinding capabilities

Heat treatment capabilities

Phoenix CNC center offers in-house design support, prototype, production

and assembly of custom parts and systems. It uses state-of-the-art

technology enabling us to work with a wide range of materials, from plastic to

titanium.

We believe that quality is the soul of an enterprise. Quality is our main concern

and top priority; all the parts Phoenix manufactures have to pass strict

inspection before being shipped.

Hygiene Industry

Phoenix CNC center is specialized in manufacturing precision components for

the hygiene industry. It uses the latest technology of tooling to be able to deal

efficiently with hardened materials; our highly skilled machinists are

experienced; working with tight tolerances. We can select the most suitable

material/hardness for your special application and provide a solution in a

timely manner.

Our products include:

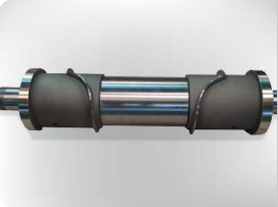

Forming pockets and drums

Vacuum drums

Rotary die cutters for baby and adult diapers

Rotary die cutters for sanitary napkin

Anvils

Crimping rolls

Knives and anvils for cross cutting

Various hardened metal parts

Industries Served

After years of growth, capital expenditures

and experience in serving a

broad range of industries, we have

recently refined our focus to address

4 distinct industrial sectors:

Pharmaceutical industry

Hygiene industry

Cement industry

Flexible packaging & food industry

Job Change Parts for the Pharmaceutical Industry

Since 2003, Phoenix CNC Precision Machining Center started manufacturing

blister tooling for PVC, and Alu/Alu blister machines.

We have acquired expertise in manufacturing change parts for various makes

of rotary and flat blister machines. We also regularly provide change parts

suitable for the following makes of blister machines:

Uhlmann IMA Hoong-A

Klockner Bosch Servac

CAM Rohrer Gamma

Our commitment to quality, perfection and consistency has led us to invest in

state-of-the-art systems, processes and facilities.

Our available tools include:

Forming stations

Guide tracks or rails

Upper and lower sealing plates made of Alumec 89, stainless steel or

hardened tool steel

Sealing drums

Perforating stations

Punching stations

Simtap

Tablet feeding systems

Customized vibratory feeders and brush box

Personalized Customer Service

Phoenix engineers provide personalized customer service through close

coordination with their customers:

Based on customers’ products specifications, Phoenix provides a complete

layout engineered and designed on its CAD systems, along with a quotation

for the required tooling within one week.

Upon approval of the blister layout, the team designs and manufactures the

tooling at Phoenix facilities in a short lead time.

Phoenix installs the change parts at the customer site and assists in the

production of the first batch.